Key Data

Manufacturer Voith

Original year of made 1970

Main rebuilds • 1995 by Voith -> DuoFormer D

• 1995 by Voith -> Film press Speedsizer

• 1999 by Voith -> Headbox: Module Jet Dilution Water

• 2006 by Voith -> steam and condensation system

• 2007 by Voith -> V.I.B. Steam-Box

• 2008 by Voith -> Pope reel rebuild

• 2008 by ABB -> New drives

• 2013 by PGA -> Surface Filling Plant

Type Fourdrinier with DuoFormer D

Paper grades WFC + WFU (Woodfree coated & uncoated paper)

Raw Material Virgin Fiber

Grammage range 40 - 145 g/m2

Paper width reel 5.475 mm

Operating speed Max. 950 m/min

Design speed 700 m/min

Capacity 170.000 tpy

Approx. 500 tpd

Drive side Right (from headbox to pope reel)

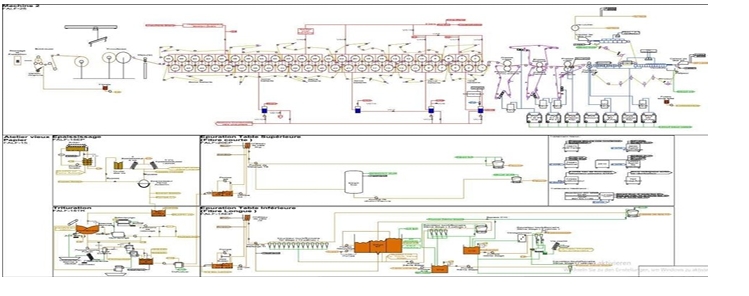

Scope of equipment • Stock preparation & Approach Flow System

• Headbox

• Forming Section

• Press Section

• Pre-Dryer Section

• Film Press

• Final-Dryer Section

• Calender

• Pope Reel

Spare parts Including, as far as available

Documentation Including, as far as available

Condition Machine stopped in November 2023,

very good condition

Location Europe

Stock preparation & Approach Flow System

• 2 pc Refiner for softwood (LF), made by Sprout-Bauer (Andritz) 1996, type TwinFlo 3E,

diameter 42’’, 1500 kW

• 1 pc Refiner for hardwood (SF), made by Andritz, 2005, type Papillon CC-380, diameter

380 mm, 750 kW

• 2 pc Refiner (reserve), made by Voith, 1969, type 3RS Cone Refiner, 520 kW

• 6

th

-stage Cleaning System, made by Noss, 2008/2018), equipped with:

- 1

st stage -> 500 cones, type AM80-D (year 2008)

- 2

nd stage -> 150 cones, type AM80-D (year 2008)

- 3

rd stage -> 50 cones, type AM80-D (year 2008)

- 4

th stage -> 20 cones, type AM80-G (year 2008)

- 5

th stage -> 8 cones, type AM80-G (year 2008)

- 6

th stage -> 1 cone, type HDC 150 (year 2018)

• 1 pc Pulsation damper and venting tank, made by Voith, 1969, stock temperature 40°C

• 2

nd

-stage Screening system, equipped with:

- 1

st

-stage -> 1pc Radiscreen, made by Noss, 2008, type M2000D,

hole size 1,8mm

- 2

nd

-stage -> 1pc Pressure Screen, made by Voith, 1995/2018, type VS10,

slot size 0,3mm

• Fiber recovery system, equipped with:

- 1pc Disperger (coated broke), made by Sulzer Escher Wyss, 1994, type HD4B

- 1pc Plate screen (uncoated broke), made by Lamort, 2000, type Diabolo D4,

Disc diameter 1,1m, hole size 3mm

Headbox

• Made by Voith

• Type Module-Jet

• Throughput 8200-14.000 lpm/m (max. 14.750)

• Consistency range: 0,6-1,5%

• 8 pc of rows in tube bank

• With Consistency (dilution) profiling

• Grammage profiling zone width: 64 mm

Forming Section

• Fourdrinier Type with Top Former Voith DuoFormer D

• 9 pc Dewatering suction boxes

• 23-37% dewatering to top

• Position former after breast roll: 6,4m

• 17,5-20% Dry content at the end of wire part

• Wire part from IBS with edge control

Presssection

• Made by Voith

• Type Duo Centri II with seperate 3

rd Nip (Venta-Nip)

• Press loading:

- 1

st Nip: 40 N/mm

- 2

nd Nip: 65 N/mm

- 3

rd Nip: 100 N/mm

• Dryness after 3

rd Nip: 39-42 %

• Roll Covers:

- 1

st Nip: Suction roll, drilled+grooved, Voith Solarflow, Ø 1050 mm, Ceramic roll,

Voith Terraspeed

- 2

nd Nip: Ceramic roll, Voith Terraspeed, Ø 1200 mm,Suction roll, drilled+grooved,

Voth Solarflow

- 3

rd Nip: Granite roll, Voith TopRock / 680, PU-roll, grooved, Voith G-2000

successor

• Center Roll:

- made by IBS

- type JamesRoll Superflex Twinschaber

- blade angle: 28°

- Linaer pressure: 300 N/m

- With Shower

• 3

rd press:

- Made by Cloud / Vickery

- Type Conformatic 101 / Vickery U32M

- Blade angle: 28°

- Linear pressure: 300 N/m

- With Shower

• Steam Box

- Made by Andritz, year 2007

- Position before 1

st Nip,

- Dryness improvement : 1,5-2%,

- Profiling available

Pre-Dryer Section

• 6pc drying groups with 45pc drying cylinders, Ø 1500mm

• Type of groups:

- 1

st

- 2

nd group: Slalom

- 3

rd

- 6

th group: Double row

• 3pc Heating groups

• Steam: max. 3,8 bar

• Steam & condensate system rebuild by Voith, 2006

Film Press

• Film press, made by Voith, year 1995

• Type: Speedsizer

• Nip pressure: 30 kN/m (max. 60 kN/m)

• Roll diameter: 1240mm

• Roll cover: Voith eVenfilm / Valmet SizeHawk ZL

• Roll hardness: 15/30 P&J

• Starch application: 1 – 1,5 g/m2 per side

• Starch concentration: 5 – 8%

Film Press

• Film press, made by Voith, year 1995

• Type: Speedsizer

• Nip pressure: 30 kN/m (max. 60 kN/m)

• Roll diameter: 1240mm

• Roll cover: Voith eVenfilm / Valmet SizeHawk ZL

• Roll hardness: 15/30 P&J

• Starch application: 1 – 1,5 g/m2 per side

• Starch concentration: 5 – 8%

Calender

• Made by Voith, year 1979

• Nip load: 30 N/mm

• Top Roll:

- PU-roll,

- type Voith Nonoperal S92 / Schäfer C2 VariPro,

- Hardness: 92 P&J

• Bottom Roll:

- Steel roll

- Type Küster S-roll

Pope Reel

• Made by VAS, Italy, year 2008

• Roll cover: Tungsten carbide covered steel

• Reel change: voith EcoChange with Goose neck

More information

Our specialists look forward to tackling your new project.

Get more information and a personal presentation of used spare parts from paper machine solution

.png)